Being a die-hard Star Wars fan, I totally appreciated the tongue-in-cheek "force" reference used by manufacturing technology industry veteran Greg Jones in an article he wrote.

In his article (shared with permission in its entirety below), Greg quotes a study on the troublesome skills gap in U.S. manufacturing, sponsored by The Manufacturing Institute — the authority on the attraction, qualification, and development of world-class manufacturing talent — and Deloitte. This skills gap has brought about the creation of hundreds, if not thousands, of workforce training programs aimed at developing and sharpening the necessary skills of potential manufacturing workers, including the use of the latest software technology.

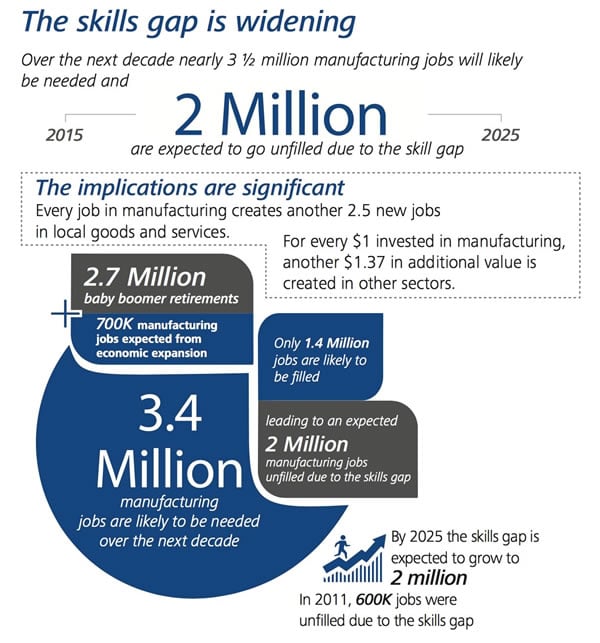

Source: Deloitte analysis based on data from U.S. Bureau of Labor Statistics and Gallup Survey.

Sensing a disruption in the (labor) force

By Greg Jones, Vice President – Smartforce Development at The Association for Manufacturing Technology (AMT) and the owner of the International Manufacturing Technology Show (IMTS)

Normally, when you think of disruptions in the labor force, you’re thinking in traditional terms like those reported by the Bureau of Labor Statistics: employment vs. unemployment, hires vs. separations in the form of layoffs or retirements, etc., and more recently “marginally attached” and “discouraged workers” who are not in the labor force.

For the purposes of this article, I’m not going to get into those who are no longer in the workforce. That’s an entirely different discussion for another day.

In the advanced manufacturing technology industry and other high-tech industries like healthcare and computer science, it’s been well documented that we’ve been challenged by the widening gap in our ability to attract skilled workers. The number of people seeking a post-secondary education or workforce training programs in our fields hasn’t matched up with the number of job openings, resulting in a scarcity in qualified job candidates.

Supply and demand works for labor too

In our industry, this supply and demand challenge certainly exists in our ability to attract engineers of all types, but it shows up more so in our ability to attract a broad range of technicians like machinists, welders, meteorologists, field service technicians and others. In fact, as we look down the road, roughly 80 percent of our workforce need will be in the technician job functions and 20 percent in engineering.

A study by Deloitte and the Manufacturing Institute last year concluded that the skills gap could grow to 2 million by 2025, due in part to retirement among baby boomers, but mostly as a result of new innovations in products and technologies and their impact on job functions. This will be especially true if we’re unable to attract young people to education programs that lead to careers in manufacturing.

Think in terms of additive manufacturing or the impact of the Industrial Internet of Things, machine learning, collaborative robotics, augmented reality, etc., on job functions in manufacturing and the ways that we recruit, educate, train and credential people for careers in those technologies.

What technological changes will impact the way materials science evolves? How will the skills of CNC machinists translate to producing parts on additive machines? When will augmented reality technology begin having a greater impact on how we educate and train field service technicians, as well as provide them with real-time access to the most updated equipment manuals right at the point of interaction with a machine?

Companies working harder to recruit

We’re beginning to see manufacturing companies provide a boost to their recruiting efforts in the form of perks and benefits, as well as redesigned office spaces to attract new employees from places like Silicon Valley. For instance, with the increase in design and development in autonomous vehicles, traditional Detroit automakers are building new facilities with sustainable, eco-friendly designs, campuses with walking trails and offices with spaces that allow for “hoteling,” for workers who are more adept at working remotely, or who travel frequently to work with partners and customers who may be located far from traditional automotive production areas of the United States.

Who would have ever thought that we’d be developing autonomous vehicles and would need workers to support design, development, production and maintenance programs around this new transportation technology? Well, I guess the producers of The Jetsons did when we were kids and we looked forward to the day when we would be traveling in flying cars. I’m still waiting patiently for that day.

Recent employment reports say that nearly 90,000 positions have been lost in the retail sector in 2017 just since the end of the holiday season at the beginning of the new year. Retail jobs are generally low-skill, entry-level positions, but are also a lifeline to work for the young and old alike. The disappearance of these jobs will continue to have a dramatic impact on these workers as companies like Amazon dominate the retail marketplace with an online model and future drone delivery.

The good news is that Amazon and others have “big boxes” sprouting up around the country leading to construction jobs and then warehousing, logistics and delivery jobs. The key is whether traditional retail workers will seek the education and training programs they’ll need to fill those jobs or seek training for jobs in other industries like manufacturing.

As we work on developing and updating existing education and training curriculum and standards, we have to be more mindful than ever of the next new disruptive technology that takes hold and will require new and different degree, certificate, internship and apprenticeship programs so that we can assure that we have an ongoing pipeline of qualified people for the manufacturing workforce.

You can follow Greg on Twitter at @gregoryajones, see his original article on the AMT website and read The Manufacturing Institute's complete study: The skills gap in U.S. manufacturing.