FABTECH Canada was my first international trade show and my first time visiting Canada, not to mention meeting Canadian experts in the industries of metalforming, fabricating, welding, and finishing. Visiting the Toronto Congress Centre, attendees sought opportunities to think, learn, and network, especially international growth strategy for manufacturers.

As a member of Fabricators & Manufacturers Association International (FMA), the professional organization serving the metal processing, forming and fabricating industry, I have a better understanding of the manufacturing challenges of a large segment of our customers. FMA is a co-sponsor of FABTECH, a convenient ‘one-stop shop’ venue where you can meet with world-class suppliers, see the latest industry products and developments, and find the tools to improve productivity, increase profits and discover new solutions for metal forming, fabricating, welding and finishing needs. There were also thought-provoking keynotes, panels sessions, and information-packed breakout sessions focused on addressing the opportunities and challenges that exist in their industries.

In all, 7,600+ attendees toured across over 98,000 square feet full of today’s most innovative products in the world of manufacturing.

FABTECH Canada also gave me the chance to explore Toronto, Canada's largest city and North America's fourth largest!

At FABTECH Canada, automation and robotics stole the show. Manufacturers are using automation and robots to overcome inefficiencies, lower costs, increase productivity, and gain market share. The most impressive robot on display was the FANUC seven-axis R-1000iA/120F-7B, which has a payload of 120kg and a maximum reach of 2,230mm. The seventh axis allows the robot’s J2 arm to fold into itself, making it shorter and able to operate in very tight workspaces.

FANUC 7-Axis Spot Welding R-1000iA/120F-7B 7-Axis Robot Spot Welding

The YuMi - 14000 by ABB Robotics serving coffee to attendees

KUKA displaying a couple of their welding robots

The expo hall stayed busy. We talked to several business owners and employees about the the manufacturing challenges they face, their technology strategies (or the lack thereof) and the need for an integrated software solution. Whether weakness lives in poor accounting practices, distribution channels, plant floor operations and/or sales management, small and large businesses alike experience the same difficulties: much needed improvements in their workflow processes.

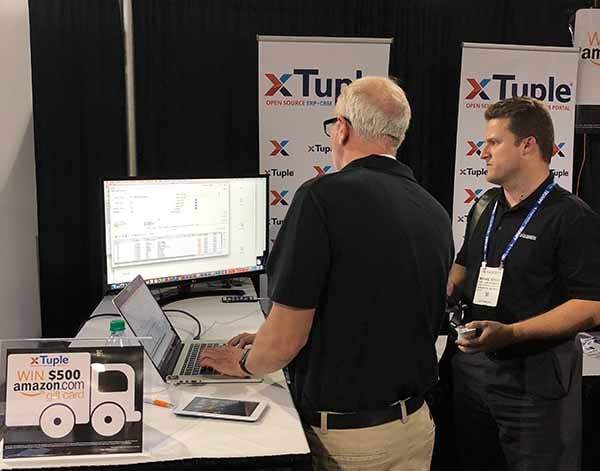

Canadian consultants Kathy Michienzi of KMichienzi Consulting (Toronto) and Bernard Le Jour of AS Plus Informatique Inc. (Montreal) joined us for the entire three-day show. Both were huge helps when the booth was buzzing with lines of people waiting for help with their enterprise resource planning / ERP selection process. Bernard was especially helpful with our French-speaking visitors.

Bernard, Wally, me (Matt), and Kathy

Demonstration time

![]()

The iconic CN Tower

Check out more pictures and videos of the robots at FABTECH (annually in U.S., biannually in Canada) or on our Facebook or Flickr.

Contact

xTuple

A CAI Software Company

24 Albion Rd, Suite 230

Lincoln, RI 02865

+1-757-461-3022

About

"xTuple" (verb) — to grow; to increase exponentially. Our mission is to help manufacturing and inventory-centric companies use management software and best practices to grow their business profitably.